Enbridge Leak Information System

The Enbridge Leak Information System (ELIS) marks a significant milestone in the realm of hydrocarbon leak detection. This comprehensive case study delves into ELIS’s journey from its conceptualization to its operational deployment, emphasizing the profound impact it has had on user experience (UX) and operational efficiency. By integrating user-centered design with state-of-the-art technology, ELIS addresses critical challenges in leak detection, especially in remote and unstaffed areas, offering a cost-effective and efficient solution that reduces installation costs by 32% and operational time by about 75%.

The ELIS (Enbridge Leak Information System) project significantly advances hydrocarbon leak detection, integrating user-centred design with cutting-edge technology. This comprehensive case study explores the ELIS system from inception to deployment, emphasizing its impact on user experience (UX) and operational efficiency.

Design Thinking & Product Strategy

20 months duration

Figma, Outsystems & Adobe Creative Cloud

User Experience Lead in Agile team

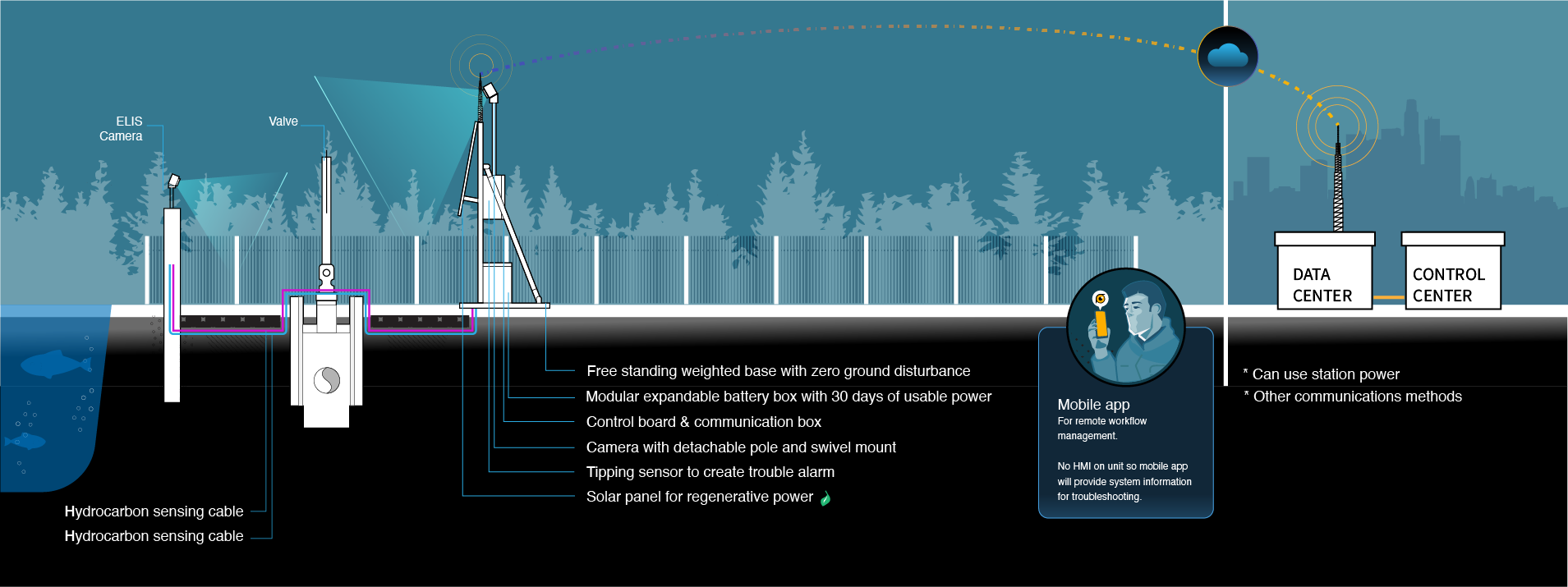

The system's modular and scalable architecture allows for integration with various technological platforms, including Azure Tech, IoT Hub, and Blob Storage. This flexibility ensures that ELIS can adapt to different environments and operational needs, making it a versatile tool for a wide range of leak detection scenarios.

ELIS significantly reduces both the installation costs and operational time. By cutting installation costs by 32% and operational time by about 75%, it presents a cost-effective solution for companies, reducing the financial burden associated with leak detection and maintenance.

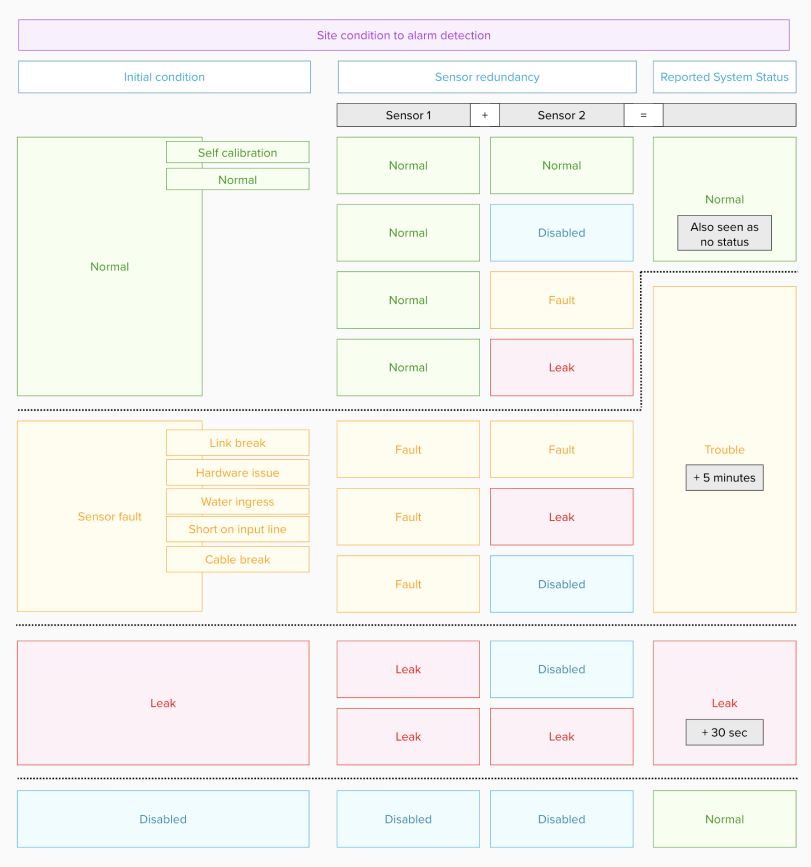

ELIS excels in detecting hydrocarbon leaks, especially in remote and unstaffed locations where traditional methods are less effective. Its advanced sensors and digital cameras, coupled with real-time data transmission, enable early detection of leaks, mitigating environmental risks and potential operational disruptions.

The dangers of small hydrocarbon leaks underscore the need for vigilant monitoring, rapid detection, and effective response strategies to mitigate their multifaceted risks.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/PY5SAGCSDVJ4DH44MNIBESCV24.jpg)

TC Energy Corp, the operator of the Keystone pipeline, attributed a combination of factors, including bending stress on the pipe and a weld flaw, as potential causes of the oil spill in rural Kansas. This incident led to the shutdown of their 622,000-barrel-per-day pipeline on December 7, after it spilled 12,937 barrels of oil. TC Energy also projected $480 million in costs related to the spill

Hydrocarbon leaks, particularly small and undetected ones, pose significant dangers to the environment, human health, and operational safety. While large spills often receive immediate attention, small leaks can be equally hazardous over time. These leaks, often from pipelines or storage facilities, release hydrocarbons like methane and other volatile organic compounds into the environment.

The environmental impact of these leaks is substantial. Methane, a potent greenhouse gas, contributes significantly to climate change, having a much greater impact on global warming than carbon dioxide over a short term. Small hydrocarbon leaks can also lead to soil and water contamination, affecting local ecosystems. Wildlife and aquatic life can suffer from exposure to these pollutants, leading to disrupted habitats and food chains.

For human health, prolonged exposure to hydrocarbons can cause a range of health issues. These include respiratory problems, neurological effects, and even cancer in cases of long-term exposure. Small leaks in populated areas or near water sources are particularly concerning due to the direct risk they pose to human populations.

Regarding operational safety, these leaks often indicate larger systemic issues in pipeline integrity and maintenance. Undetected or ignored, they can escalate into major leaks or explosions, as evidenced by numerous industrial accidents. Moreover, small leaks can be financially burdensome over time, leading to significant product loss and operational inefficiencies. They also pose legal and reputational risks for companies due to increased regulatory scrutiny and public concern over environmental safety.

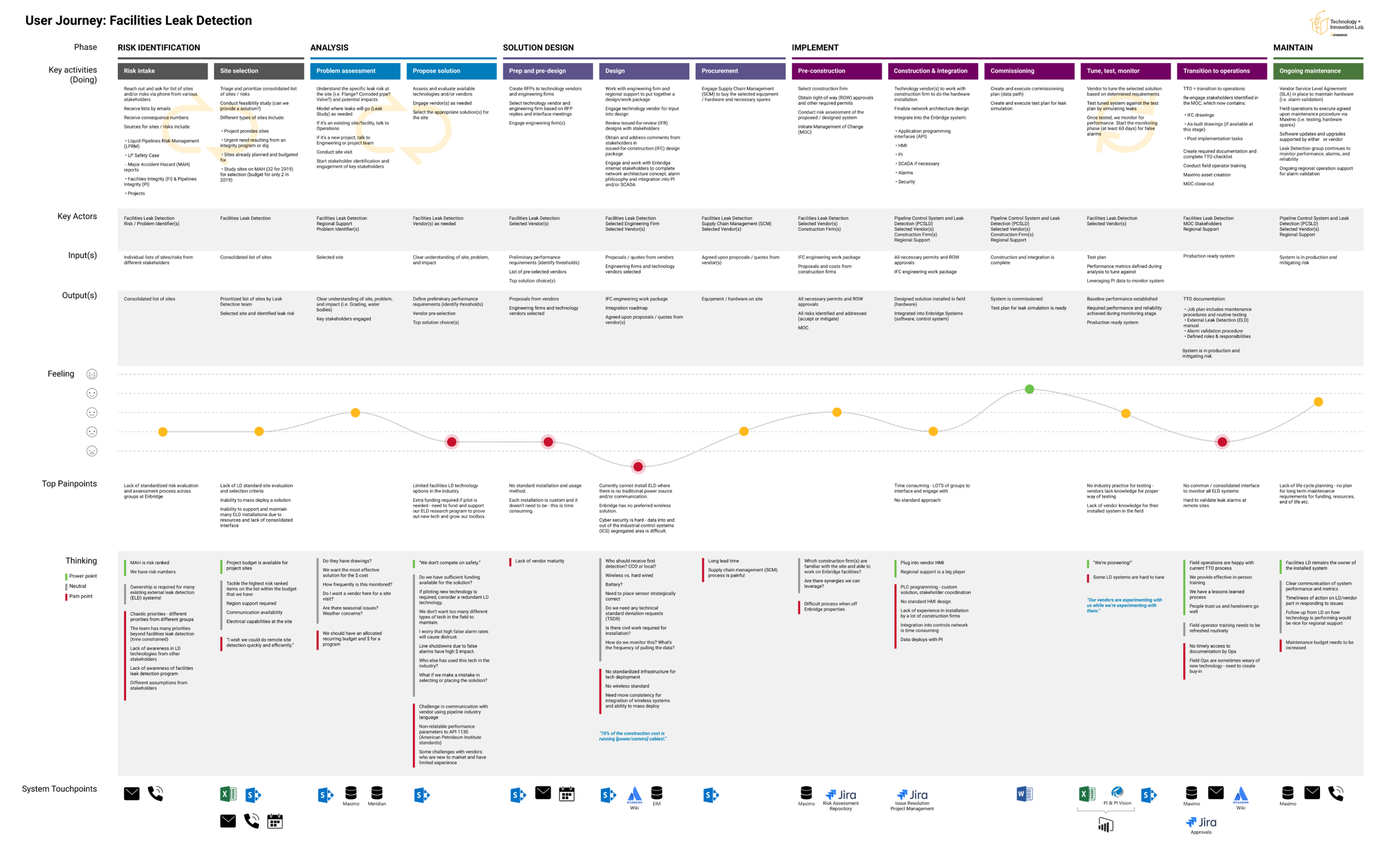

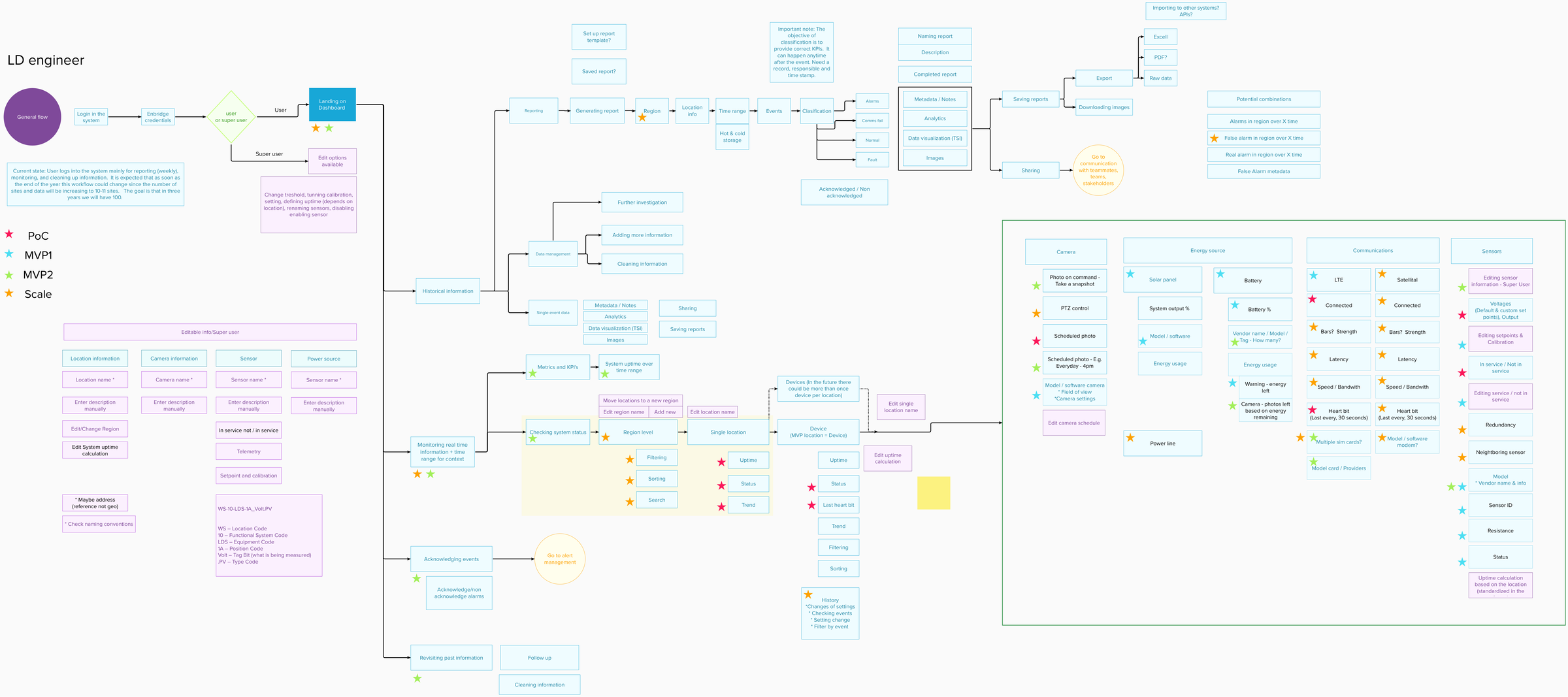

The development journey of ELIS involved several phases, from idea inception to discovery, MVP (Minimum Viable Product) scope definition, sprint planning, and execution. This process underscored the importance of agile methodology in developing a responsive and user-focused system.

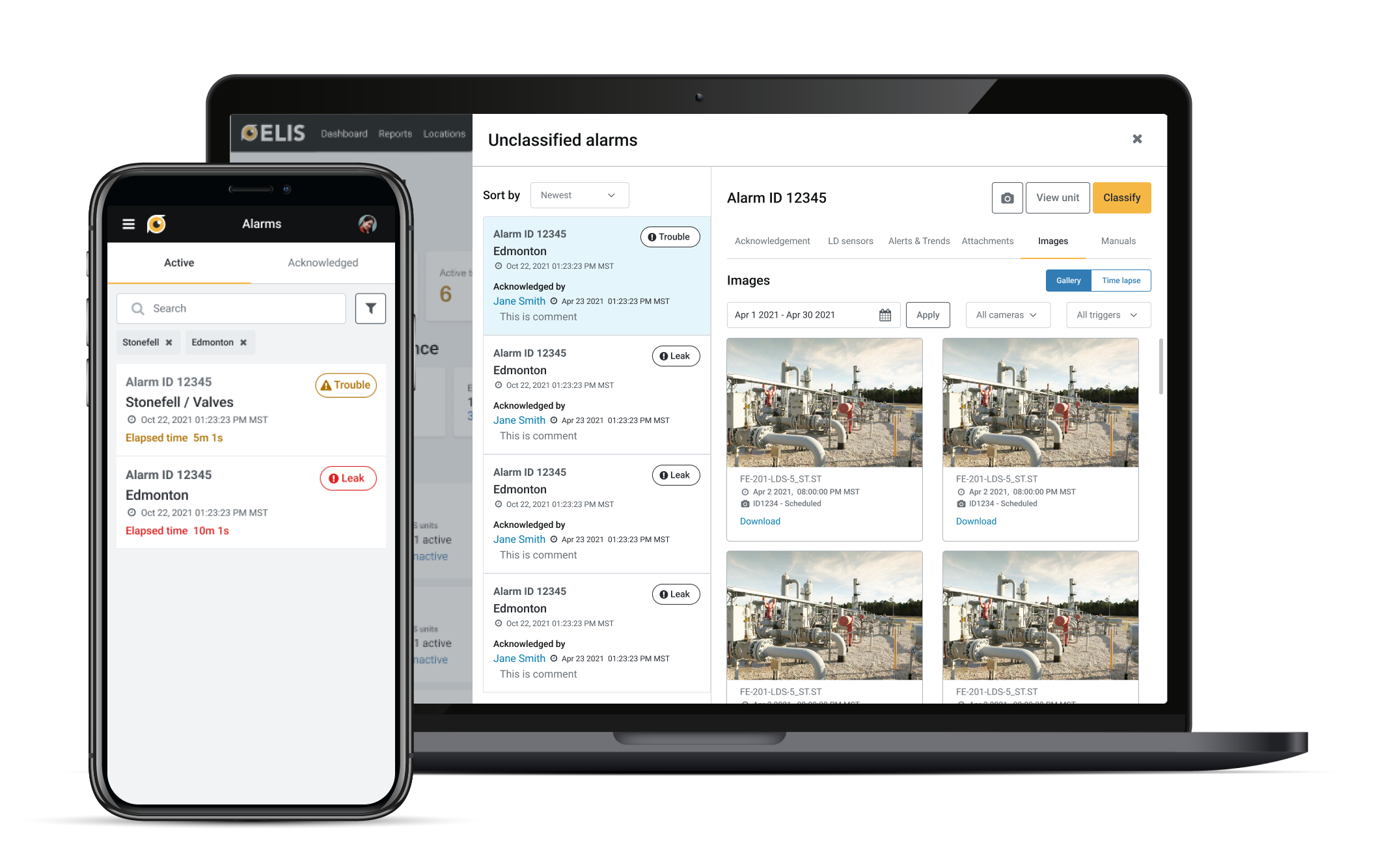

The development of ELIS faced challenges such as integrating diverse technologies and ensuring system reliability in remote locations. Solutions included adopting a modular design and focusing on user-friendly features.

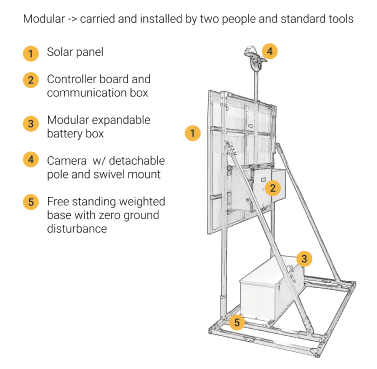

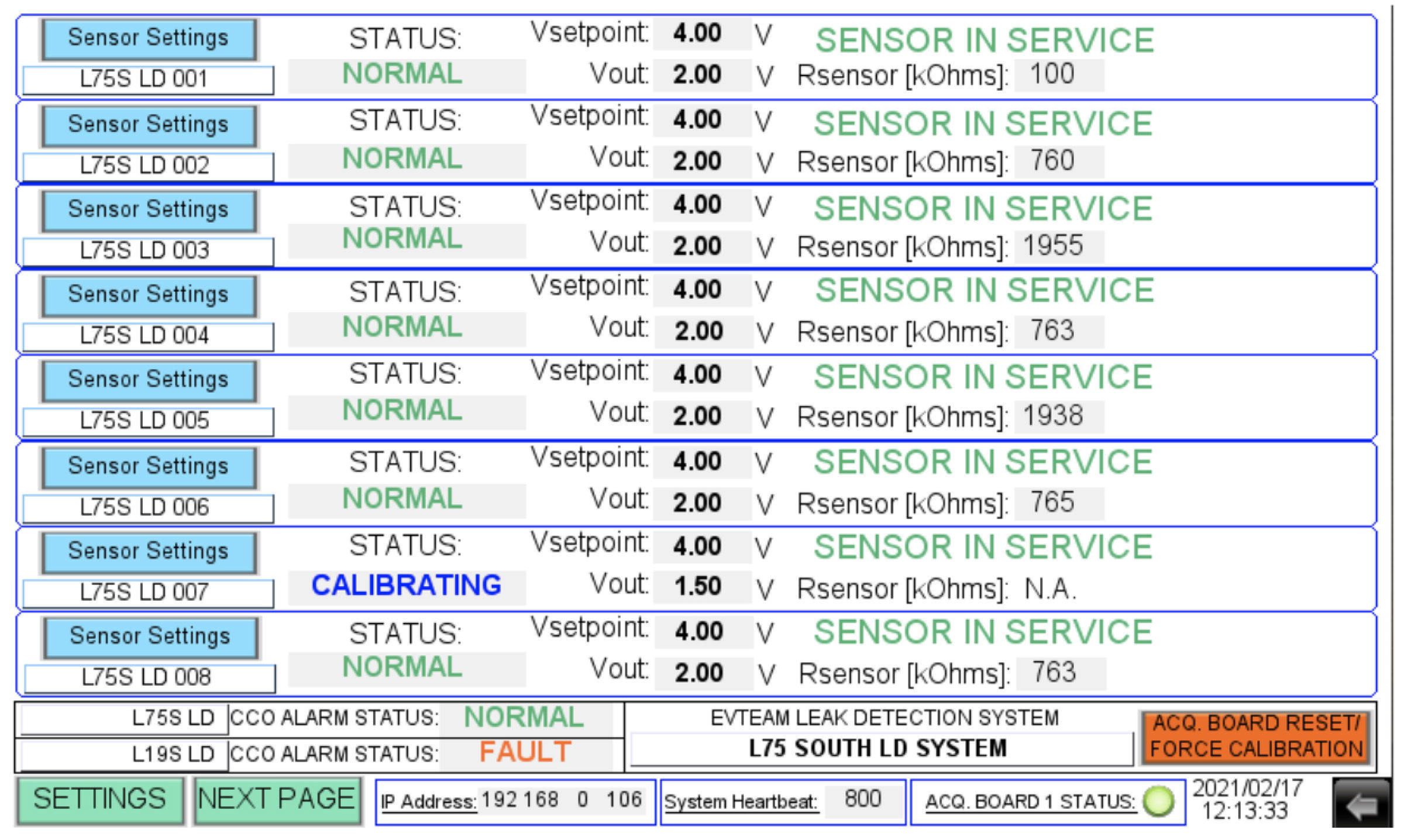

The ELIS (Enbridge Leak Information System) boasts a sophisticated and integrated system architecture designed to revolutionize hydrocarbon leak detection. At its core, ELIS combines an array of digital cameras and sensitive hydrocarbon sensors with robust solar panels and batteries, ensuring reliable, self-sufficient operation even in the most remote and unstaffed locations.

This hardware is seamlessly integrated with advanced LTE communication panels, facilitating real-time data transmission and connectivity. On the software front, ELIS leverages Azure Tech for cloud computing capabilities, utilizing IoT Hub for device management and Blob Storage for handling vast amounts of data. This harmonious integration of hardware and software components not only enhances the system's detection capabilities but also ensures scalability and adaptability to various operational environments.

The architecture of ELIS, thus, represents a meticulous blend of modern technology and user-centric design, tailored to meet the challenging demands of hydrocarbon leak detection with efficiency and precision.

These cases are perfectly simple and easy to distinguish. In a free hour, when our power of choice is untrammelled and when nothing prevents our being able to do what we like best, every pleasure is to be welcomed and every pain avoided.

ELIS is a modular, scalable platform with digital cameras, hydrocarbon sensors, solar panels, batteries, and LTE communication panels. Integrated with Azure Tech, IoT Hub, and Blob Storage, ELIS offers a holistic approach to leak detection, particularly in remote areas without power or network communication.

These cases are perfectly simple and easy to distinguish. In a free hour, when our power of choice is untrammelled and when nothing prevents our being able to do what we like best, every pleasure is to be welcomed and every pain avoided.

These cases are perfectly simple and easy to distinguish. In a free hour, when our power of choice is untrammelled and when nothing prevents our being able to do what we like best, every pleasure is to be welcomed and every pain avoided.

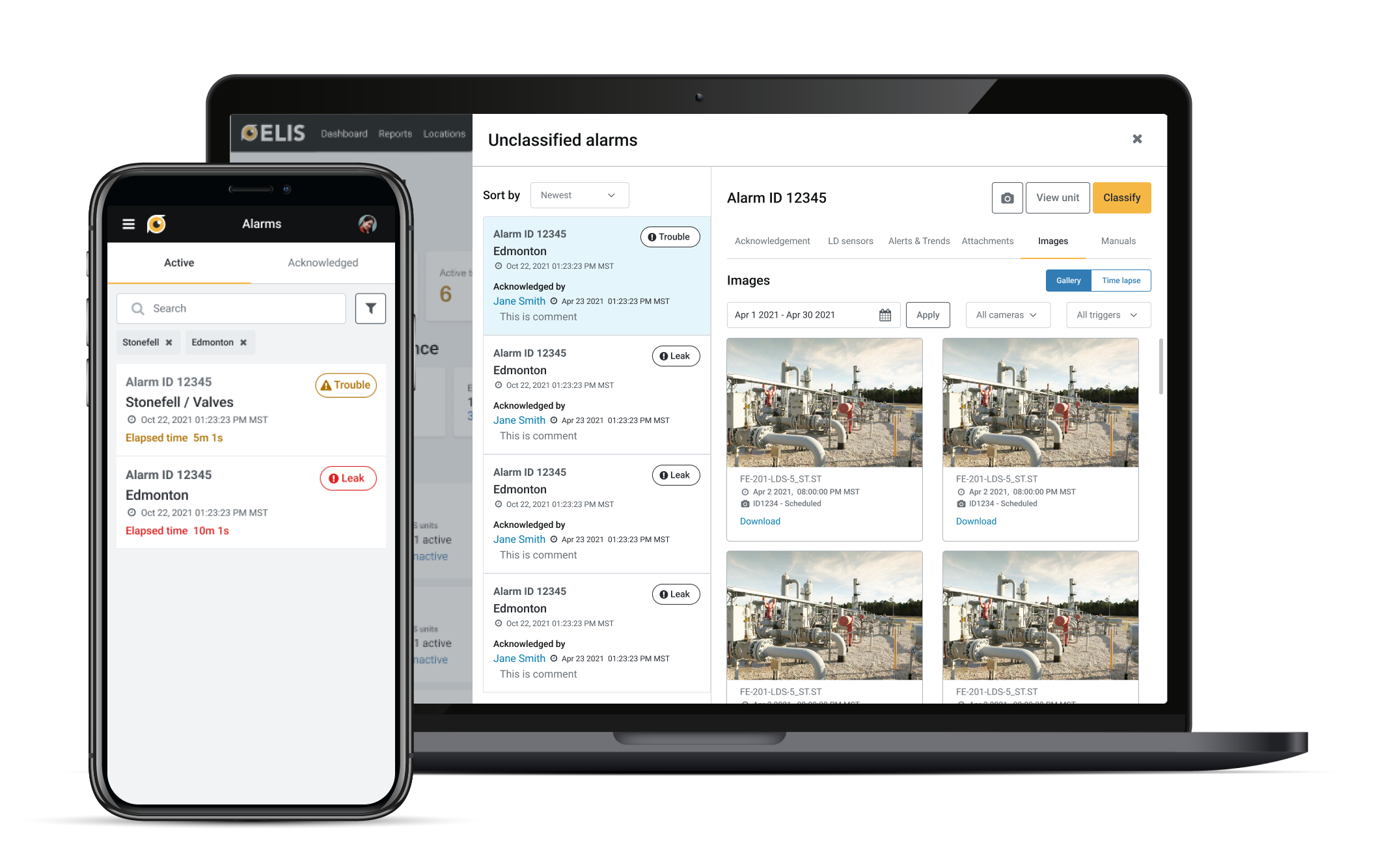

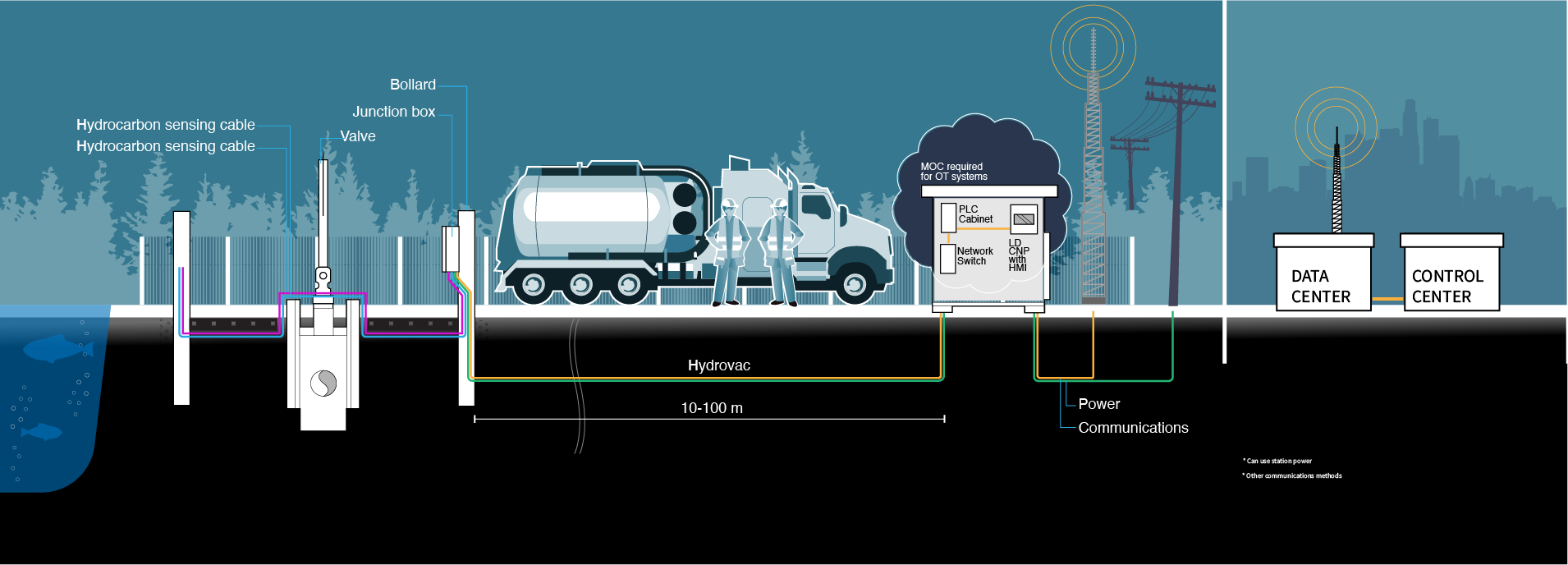

Initial research identified the needs of primary users, including technicians and engineers. Through user feedback, pain points, and requirements, ELIS was designed to address specific user challenges in leak detection.

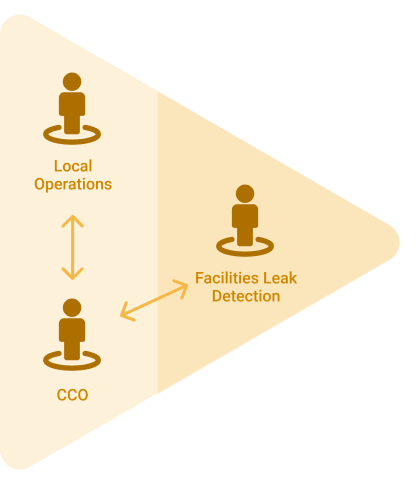

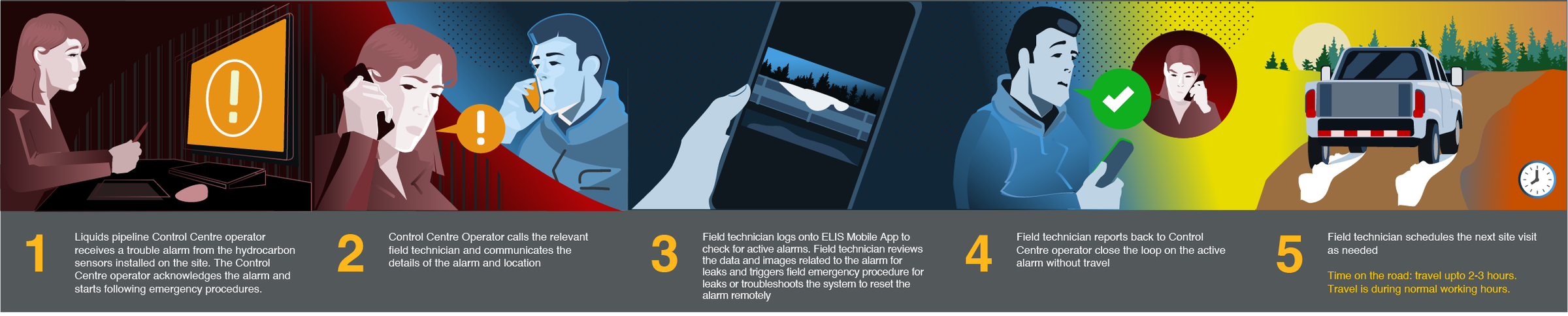

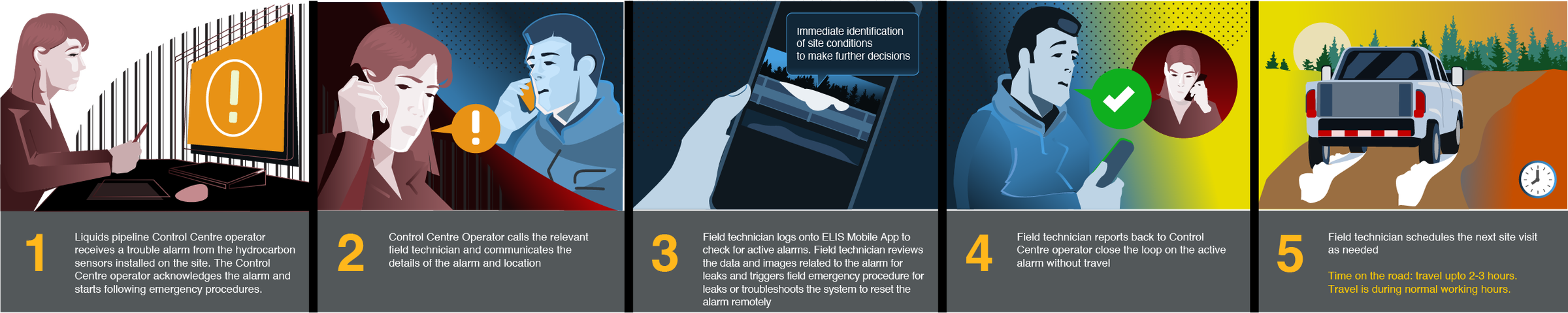

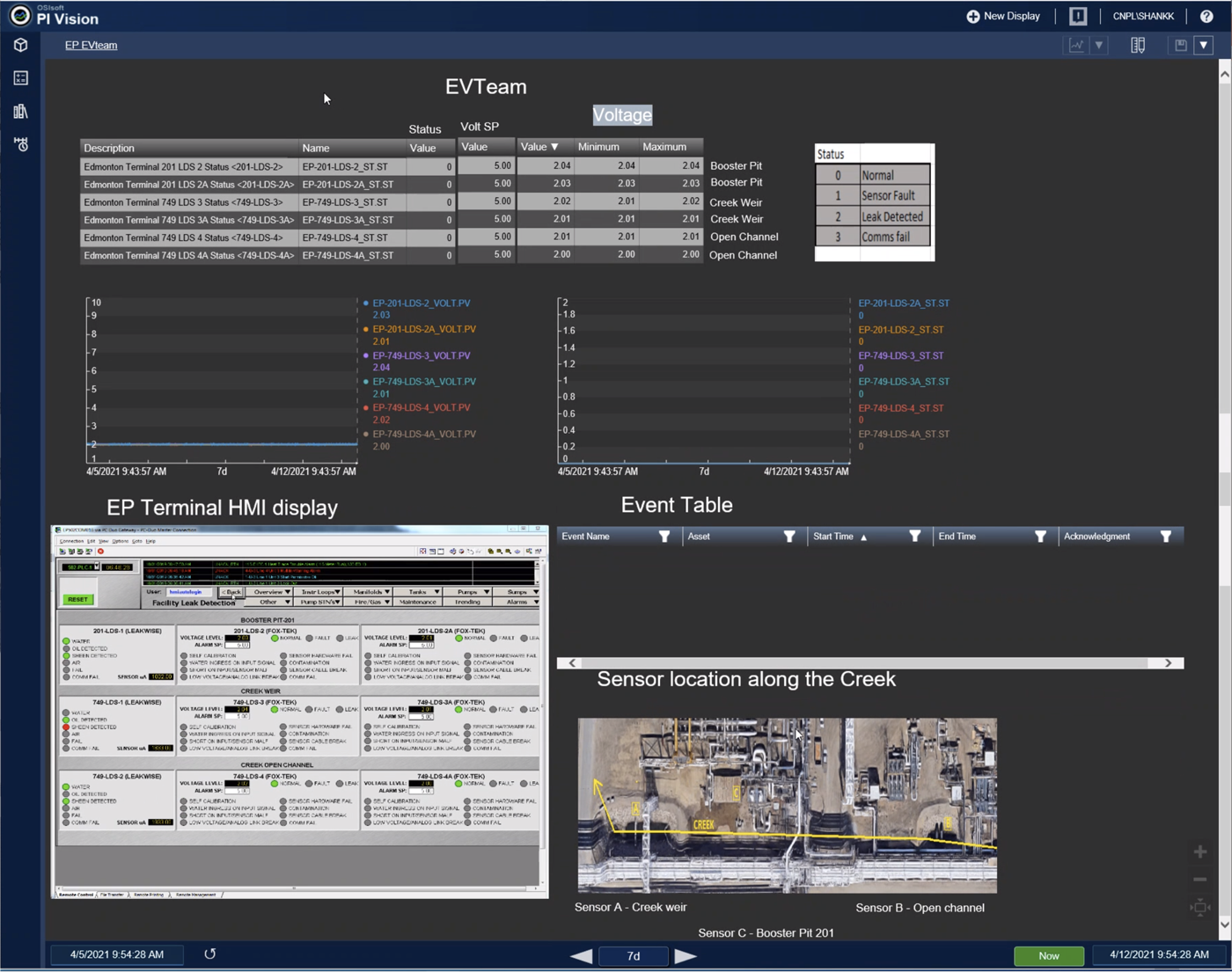

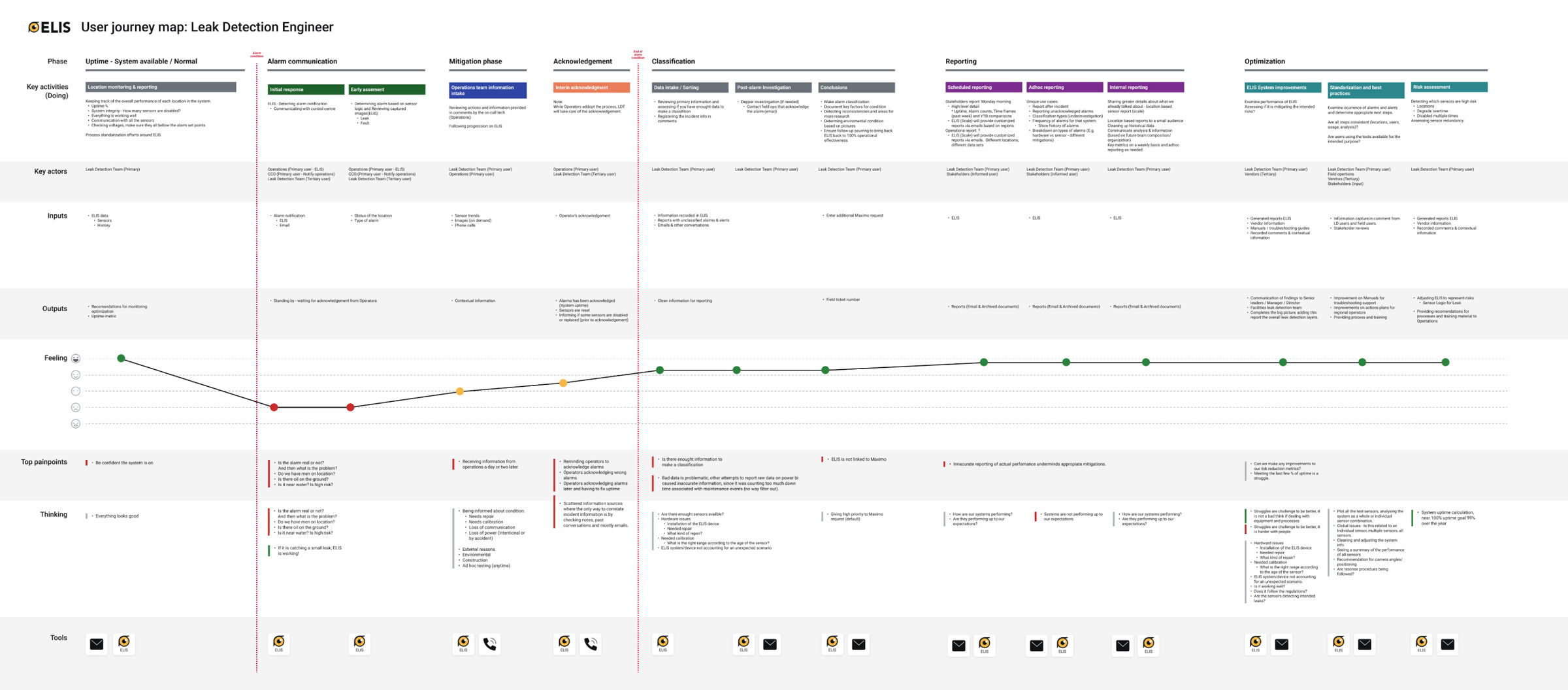

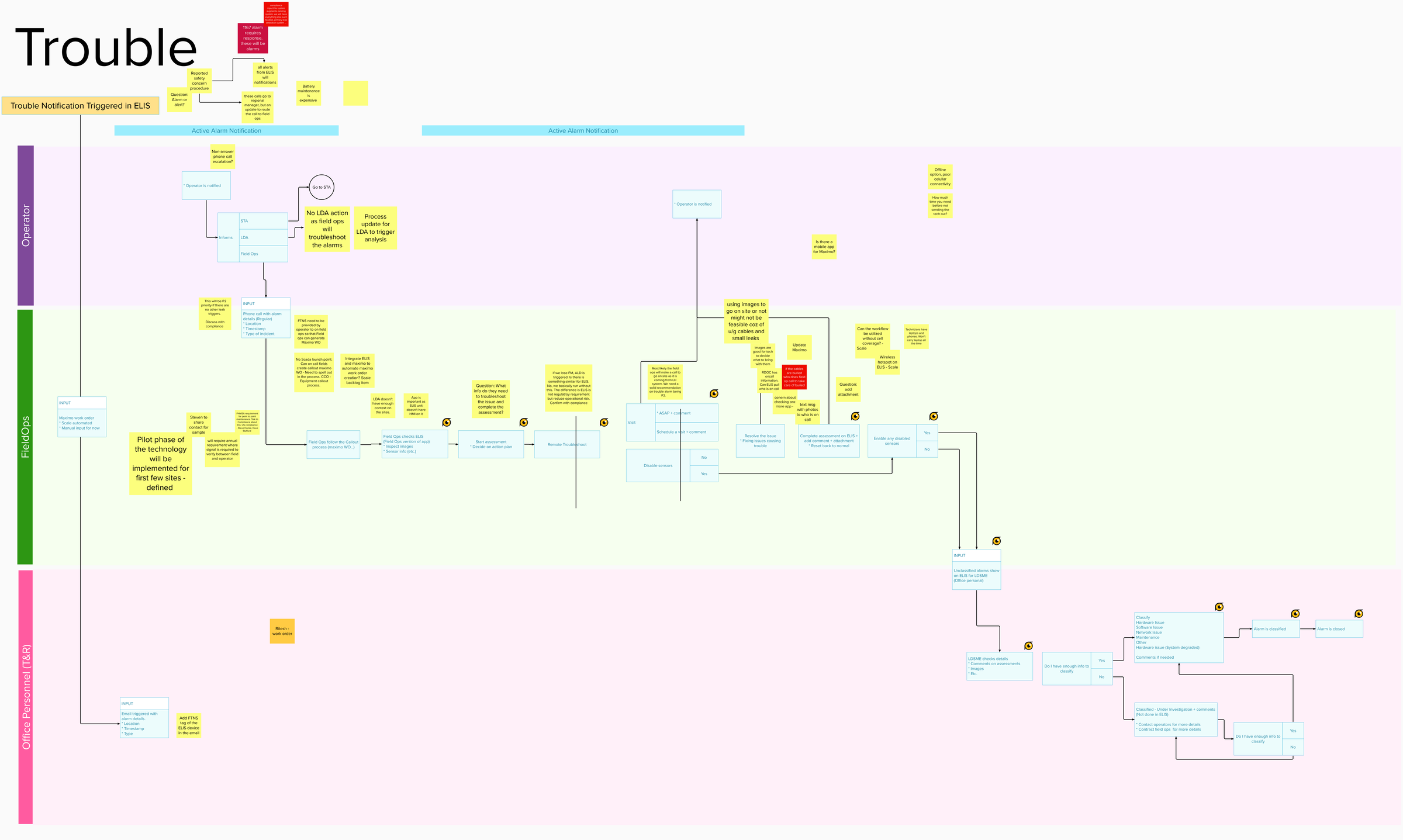

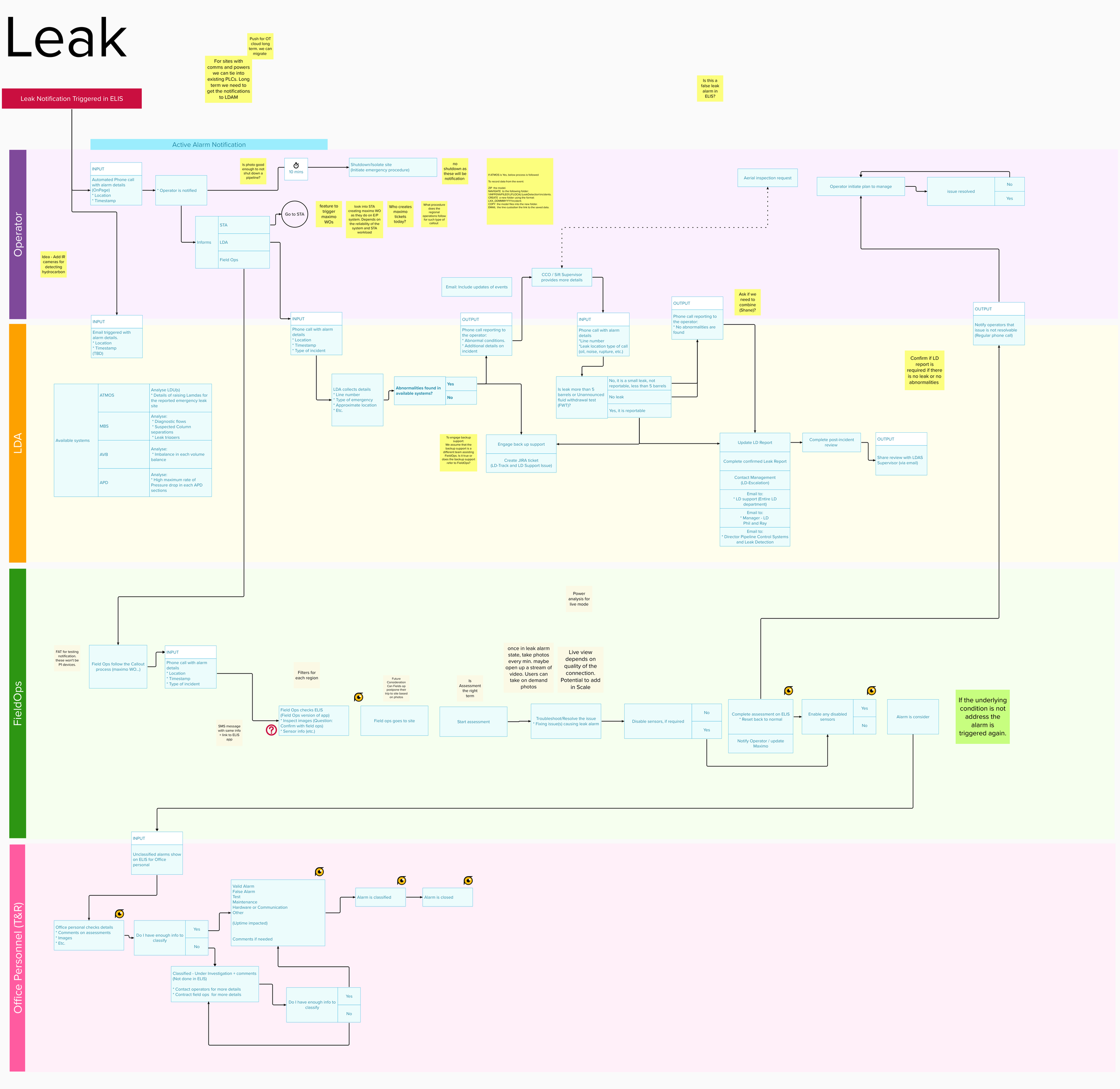

During a potential leak detection, collaboration between local operations, Control Center Operations (CCO) operators, and Facilities Leak Detection Analysts is crucial for an effective response.

Local operations personnel are typically the first to respond, leveraging their on-site knowledge to assess the situation. They communicate their findings to CCO operators, who are responsible for monitoring pipeline systems and managing overall operational safety. CCO operators analyze data in real-time, make critical decisions, and coordinate response efforts. Meanwhile, Facilities Leak Detection Analysts provide specialized expertise in interpreting leak detection data, offering insights into the nature and severity of the leak. This collaborative approach ensures a swift, informed response to potential leaks, minimizing environmental impact and operational disruptions.

Scenarios: Creating personas and scenarios helped define the specific needs and contexts in which ELIS would operate.

* Idea Inception and Development Process: The ideation phase involved brainstorming and conceptualizing potential solutions, leading to the inception of ELIS as a modular, scalable leak detection system.

* Innovation Workshops and Brainstorming Sessions: These sessions likely played a crucial role in generating creative solutions for the identified problem.

* MVP and System Architecture: The MVP for ELIS was developed, incorporating technical components like Azure Tech, IoT Hub, and Blob Storage. Prototyping involved configuring these elements into a cohesive system.

Interface and Interaction Design: Prototyping also included designing the user interface and interaction flow of ELIS, focusing on usability and accessibility.

* User Feedback and Iterative Design: This stage involved testing ELIS with real users, gathering feedback, and making iterative improvements. Surveys, interviews, and usability tests were crucial in this process.

* Performance Testing and Reliability Checks: Ensuring ELIS’s performance met user expectations and system reliability standards was key during the testing phase.

ELIS project epitomizes the transformative power of integrating user experience design with advanced technological solutions in environmental monitoring. It addresses the critical challenge of early leak detection, particularly in remote and unstaffed locations, setting a new benchmark in operational efficiency and safety.

The development of ELIS underscores the importance of a user-centred approach, where feedback, inclusivity, and adaptability play pivotal roles. This approach enhances the system's functionality and ensures its acceptance and effectiveness among users. ELIS's success story is a compelling example of how innovative solutions, rooted in understanding user needs and environmental responsibilities, can significantly improve industry practices and environmental stewardship.

Results and Impact

ELIS significantly improved leak detection efficiency, especially in remote and challenging environments. The system's real-time visualization and data analysis capabilities have led to better decision-making and increased site uptime.

Lessons Learned

Key lessons included the importance of user feedback in system design and the need for agile development processes to adapt to evolving user needs and technological advancements.

On April 22, 1992, Guadalajara, Jalisco, experienced a catastrophic explosion in its sewer system, primarily caused by gasoline from a Pemex pipeline leak mixing with waste. Spanning four hours, the blasts devastated 8 kilometres of the city, affecting about 1,000 buildings.

Officially, around 200 people died, but estimates suggest more, with 1,500 injured and thousands left homeless. This disaster, marked by extensive property destruction and significant loss of life, underscored the need for improved safety standards and infrastructure maintenance.

It also led to considerable criticism of Pemex and government authorities for handling the situation.

the ELIS project epitomizes the transformative power of combining user-centered design with advanced technological solutions in environmental monitoring. It showcases how innovative, user-focused solutions can lead to significant improvements in industry practices and contribute to enhanced environmental stewardship.

I created three portfolios highlighting UX design versatility, tech leadership, and innovation across industries.

Feel free to reach out and share your innovative ideas. I'm always open to collaboration and can sign NDAs to safeguard our discussions and your unique concepts.

©2024 Berumen Design, All rights reserved.